Principle of Operation of the "Flying Saw" Control System

Automation systems for production processes are actively used today to increase labor productivity and improve product quality. This is especially relevant in conditions where mechanisms have high dynamics and large inertial masses. One of the vivid examples of such systems is the device "flying saw," which is used in many enterprises for the cross-cutting of continuously moving materials. Such productions may include the manufacturing of pipes from various materials, woodworking, as well as the production of metal and plastic profiles.

Regardless of the type of product and industry, outdated systems have a similar functional scheme and operating principle. The material (profile, pipe, etc.) is continuously fed into the cutting zone. A length sensor, a material gripping system, and a saw with a feeding system are installed on the carriage. When the specified length is reached, the material is gripped, the carriage accelerates to the speed of material movement, the saw is pressed against the material, and cutting is performed. After reaching the end point, the saw returns back. After the saw returns to the initial position, the motor is activated, which returns the carriage to the starting position. Previously, purely mechanical systems were used for this, which led to significant problems.

Problems of Traditional Control Systems

During the operation of the traditional flying saw, the following problems arose:

- The direct start of the cart motor caused significant mechanical loading in the drive system, destroying the gearbox and breaking the chain;

- The maximum line speed rarely exceeded 60 meters per minute;

- Difficulties in coordinating the flying saw's operation with the production line.

Modern control systems significantly simplify the system and reduce impact loads.

Features of the Upgraded "Flying Saw" Control System

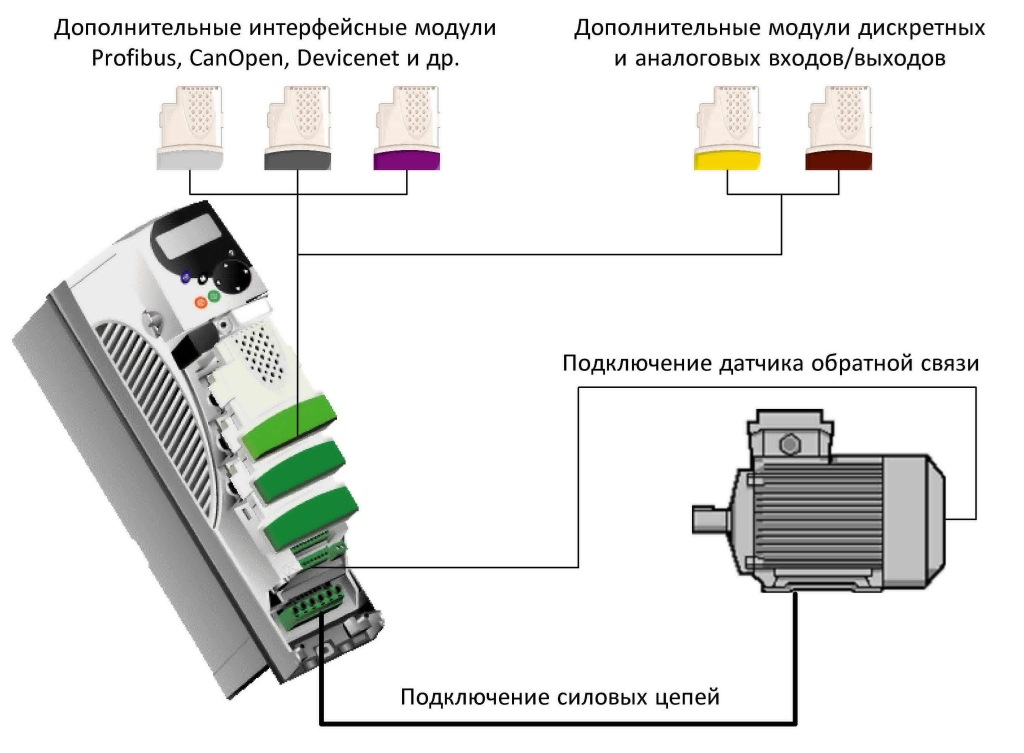

As part of solving the problems, we developed a system based on a frequency converter with a Delta Electronics C-2000 controller module, which controls the cart's movement motor. The controller performs all necessary operations for data collection, processing, and task formation for cart movement. If necessary, the system can be expanded with additional input/output control modules.

The frequency converter operates in vector mode with feedback on the motor shaft's speed. Usually, an encoder is used as a feedback sensor, although a resolver can be used for particularly heavy conditions. The main advantage of the new system is that it works with standard asynchronous motors, which are inexpensive and require no maintenance. This allows for the installation of the control system at minimal cost.

Advantages of the Upgraded System

Testing showed that upgrading the "flying saw" significantly improves product quality by increasing cutting accuracy and eliminating the aforementioned problems. Among the main advantages of the system:

- Standardization of the solution, allowing it to be used as a standalone system or as part of a larger control system;

- Significant increase in cutting accuracy due to the use of high-precision measurement equipment;

- Reduction of loads on the mechanical components of the system due to the absence of impact starts;

- Absence of mechanical effects on the material, preventing its deformation;

- Ability to significantly increase line speed, limited only by cutting accuracy;

- Control of additional equipment such as pushers, accumulators, etc.

For any questions, you can send us a request via email at info@chastotnik.ua or by phone at (044) 337-0-334.