Introduction to Lifting Cranes

Lifting cranes are cyclic mechanisms designed for the vertical and horizontal movement of loads. The main components of a crane include a movable platform and a winch. Early models of cranes were made of wood, had a manual drive, a low lifting capacity, and a limited radius of operations.

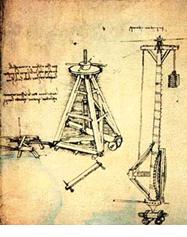

Fig. 1: Lifting devices by Leonardo Da Vinci

Historical Development of Technologies

In the early 19th century, metallic cranes appeared in England, which used steam engines for the winch, and later hydraulic engines. By the late 19th century, cranes began to be equipped with internal combustion engines, and later with electric motors, which proved to be the most effective for moving loads.

Fig. 2: Rotating tower crane with extension

Types of Electric Motors in Lifting Devices

Various types of electric motors are currently used for lifting loads and moving grabs:

- Asynchronous with a phase rotor

- Asynchronous with a squirrel-cage rotor

- Direct current motors

Operating Modes of Crane Mechanisms

Crane mechanisms operate in short-term (S2) and repeated short-term (S3) modes, which require frequent starts of the electric motors. Asynchronous motors with a phase rotor have low starting currents, achieved by using a rheostatic start. However, the use of such motors has some drawbacks, including the need to maintain a large amount of contact equipment.

Alternatives and Improvements

Direct current motors provide smooth speed control, which is important in cases where precise control is required, for example, in high-rise construction. Speed control is achieved in this case using thyristor converters.

Asynchronous motors with a squirrel-cage rotor are typically used when there is no need for speed control. They are characterized by a simple design, reliability, and lack of maintenance requirements. With the advent of frequency converters, allowing speed regulation, asynchronous motors have become more versatile in use.

Requirements for Frequency Converters

Frequency converters used in cranes must meet certain requirements:

- Vector control for dynamic drive operation.

- Ability to maintain the required torque on the shafts of asynchronous motors at low frequencies.

- Resistance to vibrations.

- High overload capacity and a wide operating temperature range.

Advantages of Speed Regulation

Regulating the speed of motors using frequency converters allows achieving the following results:

- Simplicity in organizing the drive control system.

- Smooth acceleration and stopping of crane mechanisms.

- Compensation for displacement and movement along curved trajectories.

- Control of the electromechanical brake.

- Energy recovery during braking.

Selecting Frequency Converters

The following models of frequency converters are used for lifting and transport equipment: VLT® VLT_reg; AutomationDrive FC302 by Danfoss, ATV71 by Schneider Electric, VFD C-2000 from Delta Electronics.

Contact Information

For selecting a drive for your application, use our website or call: Kyiv, MTS (099) 091-35-02, KS (096) 017-47-29.