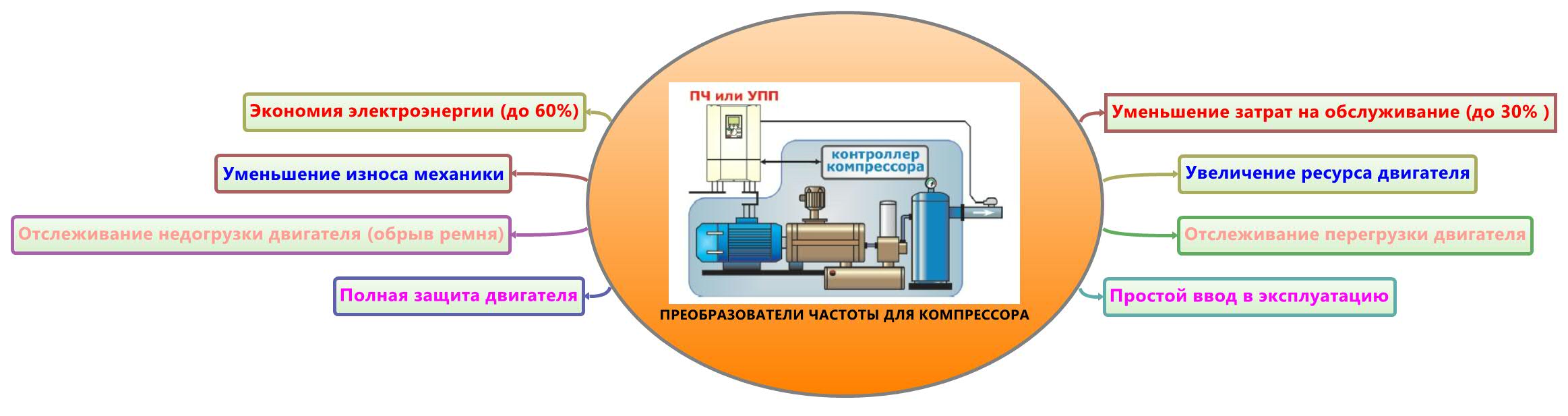

Use of Frequency Converters and Soft Starters in Compressor Equipment

This article discusses the application of frequency converters and soft starters in compressor equipment.

Advantages of Implementation

The main advantages of implementation are as follows:

More About the Benefits

Problem | Solution | Result |

When starting compressor equipment, inrush currents occur that can exceed the rated value by 7-20 times, requiring the use of larger cable sizes. This can lead to voltage drops and equipment failure. | Frequency converters and soft starters help reduce inrush currents and mechanical loads on the motor. | This leads to reduced wear on the compressor mechanics, extended motor lifespan, and decreased repair costs. |

There is a risk of breakdown for screw compressors when refrigerant enters the screw. | The overload protection system ensures emergency stopping of the compressor under a sudden load increase. | This increases the lifespan of the compressor equipment and prevents its breakdown. |

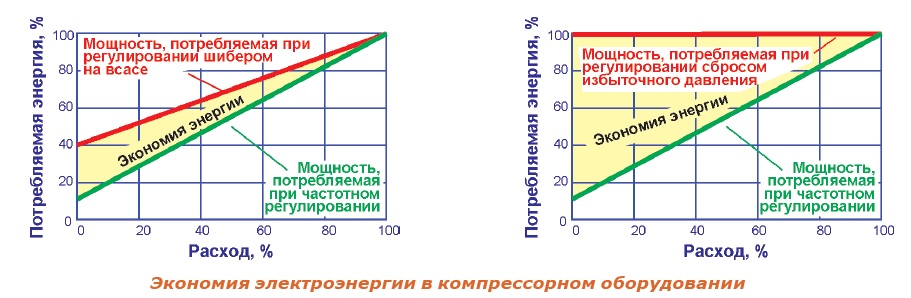

When the compressor operates in idle mode, there are energy losses and additional load on the equipment. | The use of a frequency converter with a connected pressure sensor allows maintaining pressure according to air consumption, optimizing energy consumption. | This leads to energy savings of up to 60%, allowing the equipment to pay off within a year to a year and a half. |

The use of soft starters in compressor equipment allows you to:

- Significantly reduce inrush currents and avoid voltage drops.

- Prevent belt slippage when using belt drives.

- Reduce mechanical loads on components.

The use of frequency converters for compressor equipment allows you to:

- Avoid motor overload and belt slippage.

- Save energy at levels of 20-60% thanks to the absence of the need to vent excess pressure.

- Automatically maintain network pressure with high precision.

- Pay off the implementation within up to 15 years.

If you want your compressor to be economically viable, contact our specialists in the Contacts section. We will help your compressor generate profit.