In modern industrial conditions, ensuring the continuity of production processes is a critically important aspect. One of the key elements for this is the availability of a backup power source, such as a diesel generator. This issue becomes particularly relevant for enterprises where frequent power outages can lead to significant financial losses. However, starting and operating equipment using a generator requires special solutions to stabilize electrical energy. In such situations, frequency converters (variable frequency drives) play a key role.

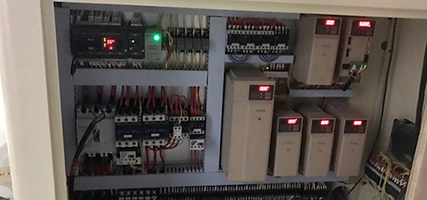

In modern industrial processes, automation is critical for achieving efficiency, reliability, and safety in production. The two main elements of this automation are industrial controllers and frequency converters, which are widely used to control various electromechanical systems, such as pumps, fans, conveyors, and other equipment.

The Internet of Things (IoT) in industry, also known as Industrial IoT (IIoT), is driving revolutionary changes in manufacturing, resource management, and process optimization. One of the key components of IIoT is the equipment that enables real-time data collection, transmission, and processing. In this article, we will explore the main types of equipment used in IIoT and their role in industrial applications.

The Internet of Things (IoT) plays an increasingly important role in the development of modern industry. This technology allows for the connection and management of various devices and systems, creating integrated networks that can exchange data in real-time. The use of IoT in industry, known as Industrial IoT (IIoT), provides numerous advantages for manufacturing, resource management, and overall business efficiency. In this article, we will explore the key aspects of IIoT implementation and its impact on industry.

The Internet of Things (IoT) is gaining popularity in the industrial sector, particularly in monitoring and management systems for washing pumps. By implementing IoT technologies, businesses have the opportunity to enhance efficiency, reduce costs, and improve equipment reliability. In this article, we will explore the main stages of IoT pump monitoring implementation and its advantages.

Frequency converters, also known as inverters or variable frequency drives (VFD), are essential components for regulating the speed and torque of alternating current electric motors. They are widely used in various industrial and residential sectors due to their ability to enhance energy efficiency, control accuracy, and reduce operating costs. Below are the main areas of their application:

Soft starters, or smooth starters, are electronic devices that provide gradual starting of electric motors by controlling voltage and current during the startup process. Unlike traditional direct starters that apply full voltage to the motor at startup, soft starters offer controlled acceleration. This reduces mechanical and electrical stress on the motor and connected equipment.

Cascade control of pumps is a method of organizing the operation of several pumps in a system to ensure their coordinated operation to achieve maximum productivity in accordance with current requirements. This method is applied in water supply, heating, cooling, water treatment systems, as well as in other industrial and commercial sectors where effective pump management is essential.