Power outages in the electrical network are not a reason to stop production. Many enterprises have other sources of electrical energy for such "surprises." A very popular option is a generator, whether gasoline, diesel, or gas-powered. This is an excellent source of electrical energy to supply many installations. However, if you need to start an electric motor from it, there are some nuances. Let's analyze this situation.

An asynchronous electric motor, whether single-phase or three-phase, has a high starting current. Let's consider the cause of its occurrence and what values it can reach.

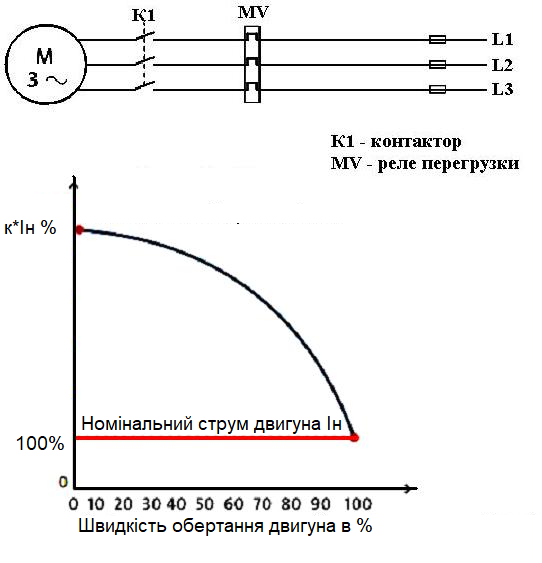

Simply put, the dependence of the current on the motor’s acceleration speed can be represented by this graph. This corresponds to when the motor is started directly from the network using a starter. Let’s analyze this graph. When the starter is not closed, the motor does not rotate. At the moment the starter closes, the motor rotor is not yet rotating, but voltage is already being applied. A moment of a sort of "short circuit" arises, and as a result, the current rises to the value k*In.

Theoretically, the current should rise to infinity, but the rotor starts to rotate. This means the "short circuit" effect decreases and the current begins to fall. A transient process follows: the motor accelerates, and the current decreases. This process settles when the motor rotor reaches the nominal speed. The current then falls to a value determined by the load on the motor (if the motor starts without load, the decrease continues to the no-load current value. With nominal load, it decreases to the nominal current In. If partially loaded, it reaches a value corresponding to its load (between no-load and nominal current). This transient process depending on the type of load turning the motor can be:

Light start - the transient process lasts 1-3 seconds, with the coefficient k ranging between 4-6

Heavy start - the transient process lasts over 15-20 seconds and/or the coefficient k ranges between 10-20

A light start usually applies to motors of pumps and mechanisms that start unloaded

A heavy start applies to fans, compressors, mechanisms that may start under load – crushers, conveyors, bucket elevators, shredders, etc.

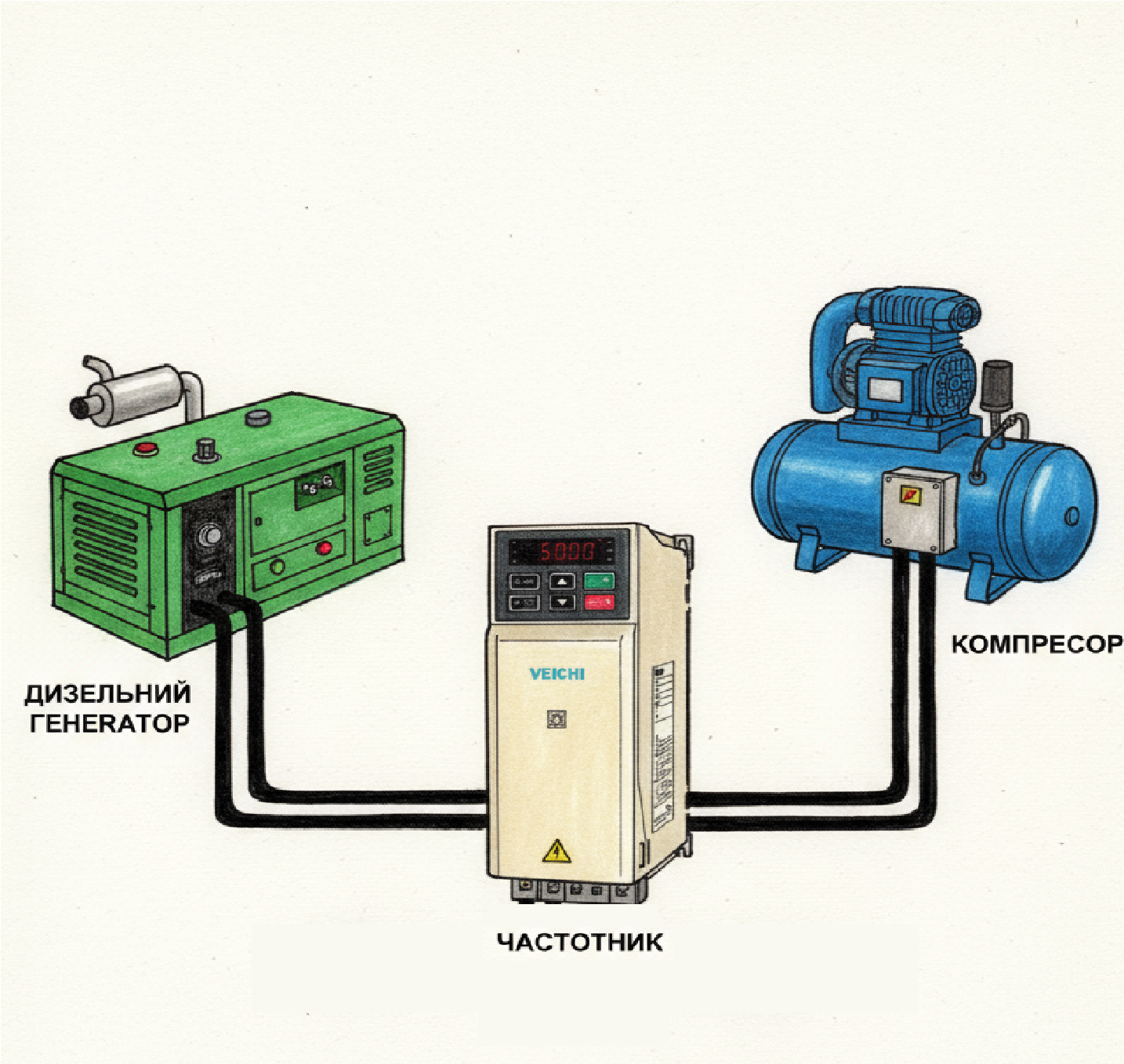

Generators have very low overload capacity – meaning they cannot supply 10-30% more than their rated power for even a few seconds. But typically, this is insufficient to start a motor. A classic client situation is, for example, a compressor with a nominal current consumption of 15 Amps (7.5 kW). To start it, a compressor capable of delivering at least 75-90 Amps (about 45-50 kW) is needed. Buying such a compressor just for starting is very impractical. However, there is an option to buy a generator with an output current of 23-28 A (about 11 kW) and start the compressor. This solution is a frequency converter. Frequency converters from the Veichi AC310 or AC10 series handle this task excellently. With proper settings, a frequency converter significantly reduces the coefficient k to 1.1-1.5. Thus, the required generator power is significantly lowered, which very substantially saves investment costs.

This solution is the most optimal, modern, and offers many advantages:

Significantly reduces starting currents

Reduces mechanical stress on compressor components

Has many protections for the motor

Extends the compressor’s service life

However, on the market, there are also soft start devices. They are cheaper than frequency converters, and some clients are tempted by the price to further cheapen the system. But here lies a catch – usually, such a system does not work properly. The reason is that the soft start device, by design, has several restrictions:

Starting is usually allowed no more than once every 10 minutes – which is not suitable for all applications

The coefficient k starts from at least 2.5 and can reach 6-9.

Therefore, when using a soft start device, a significant power reserve for the generator is also required – so this solution is also very costly.

Thus, if you need to start an electric motor from a generator, only a frequency converter should be considered. The chastotnik.ua team has extensive experience implementing such solutions. Contact us and our engineers will help solve your problem and save your costs as much as possible.