Unfortunately, electricity blackouts are currently in effect in Ukraine. These outages have affected both production and household consumers. The way out of this situation is self-generation or the use of alternative energy or the release of energy from rechargeable batteries. And usually, the situation arises where there is a single-phase power source, a single-phase generator or a single-phase inverter, and a three-phase 380V motor (pump, compressor, fan, saw, etc.) needs to be connected. And here a problem arises, but it has several solutions.

Inefficient with power loss – if possible, switch the windings in a delta connection for 3-phase 220V, and connect a working capacitor of approximately 640 μF per 1 kW of power into the circuit. The result is a power loss of the electric motor by at least 30-40%. Which most likely will not be able to work fully under load.

Use a frequency converter with an input voltage of 1-phase 220V and an output of 3-phase 220V. In this case, the motor windings must also be able to be re-connected in a delta connection for 3-phase 220V.

Using a frequency converter that converts 1-phase 220V to 3-phase 380V. Then nothing needs to be re-connected, and everything seems simple, BUT there are several pitfalls here. Let's analyze case #3 in detail.

Does a frequency converter exist that converts 1-phase 220V to 3-phase 380V? Yes, it does. But... First, let's see what well-known manufacturers of frequency converters offer, such flagships as ABB, Siemens, Danfoss, Mitsubishi Electric, Schneider Electric, Delta Electronics, Yaskawa, Lenze, Hitachi, Invertek do not have frequency converters from 1-phase 220V to 3-phase 380V in their product lines. This is alarming, but let's look at another category of manufacturers who are rapidly gaining popularity: Veichi, INVT, Inovance, Chint, Hiconics, LS Electric, Omron, Fuji Electric, Toshiba, Hyundai, Powtran. These manufacturers also do not have similar solutions. Another alarming bell. Let's not prolong the intrigue. Such solutions are available from a few little-known Chinese manufacturers; let's consider such a frequency converter.

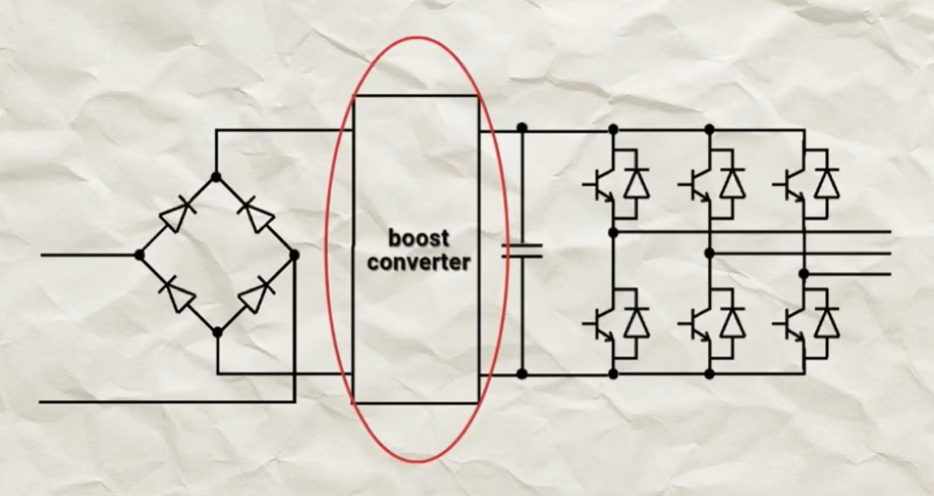

Let's consider the structure of the frequency converter

The 220V AC voltage is rectified to approximately 310V DC. Logically, a boost converter should be placed there – to boost it to 540V DC and from it create a 3-phase 380V AC voltage. But boost converters are usually used for boosting to a small voltage – power supplies that convert 12V to 24V or 30V. And usually for small powers, typically up to 500W. The main element of such a boost converter is an inductor in which energy is stored. But if we consider such a booster for a 2.2 kW frequency converter, its dimensions and weight would be three times larger than a 2.2 kW frequency converter with a 3-phase input, and the price would be 5 times higher. Therefore, if a seller claims that the frequency converter has a built-in boost converter, is the size of a regular frequency converter, and the price does not differ much, stop the conversation – the seller either does not have information about the product or is simply deceiving you. With a built-in boost converter, the frequency converter will be very bulky, heavy, and expensive, but correct from the point of view of circuitry and output characteristics.

Therefore, a different solution is used.

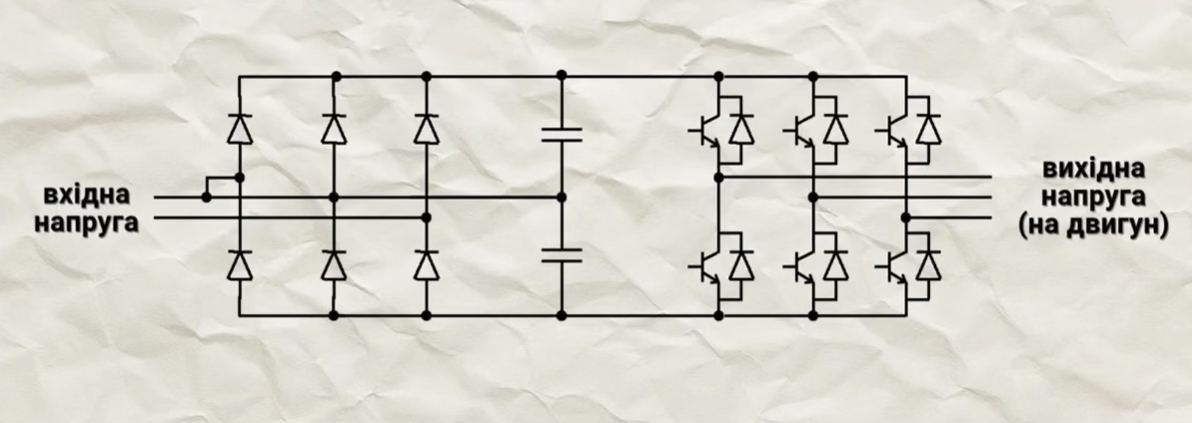

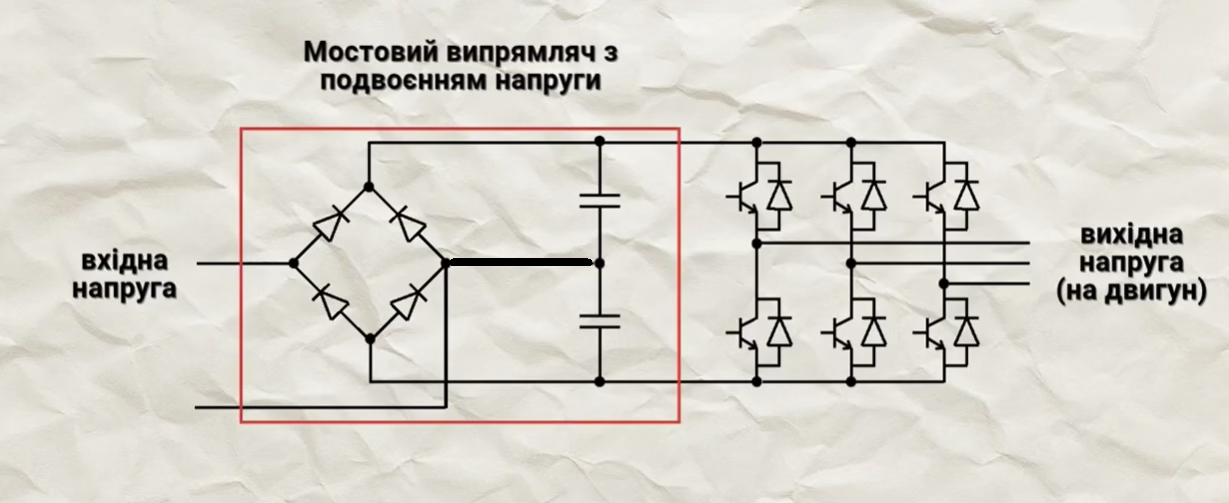

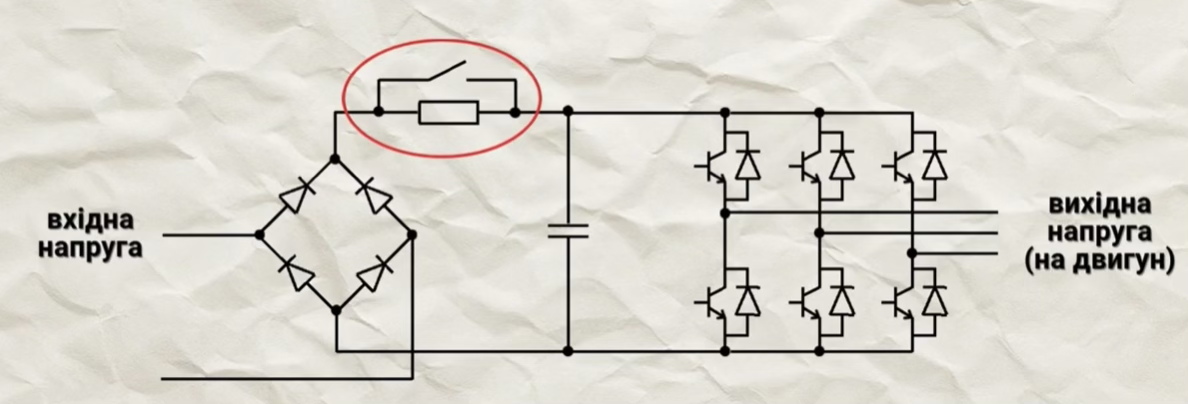

The scheme of this frequency converter looks like this

But it can be simplified to the following form

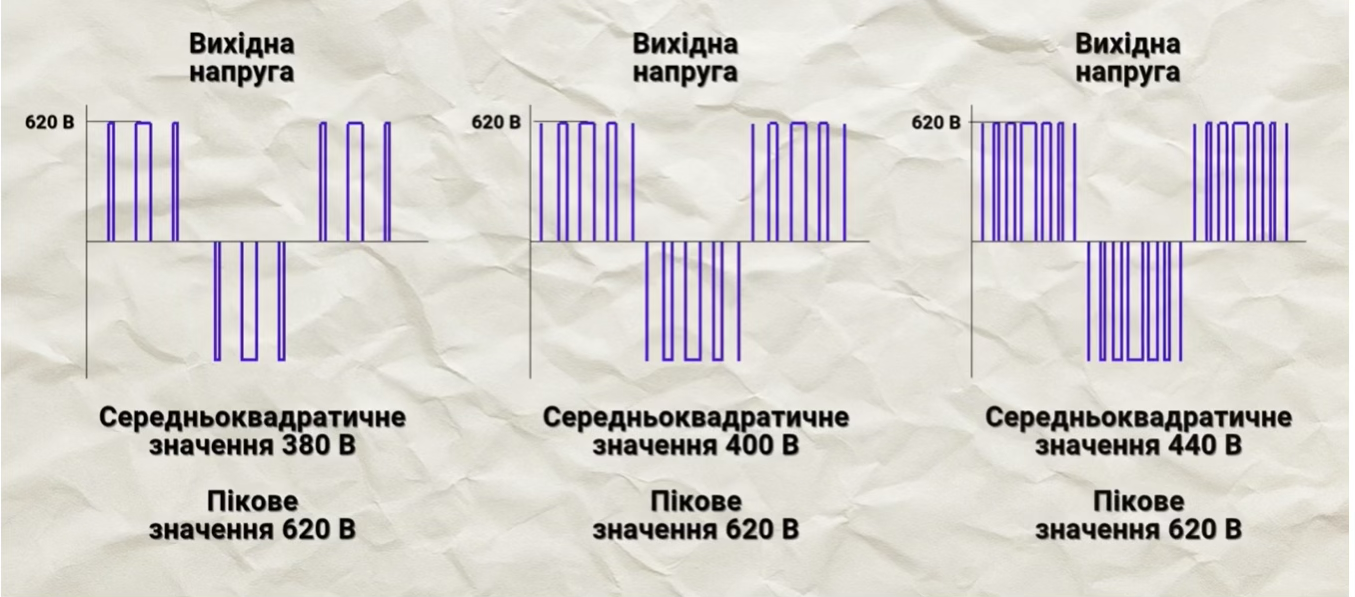

Thus, we get double the voltage of the DC link, namely not 310 but 620 Volts. With such a voltage, the inverter can "cut" the necessary voltage of 380, 400, or 440 Volts.

But let's consider the disadvantages of such circuitry

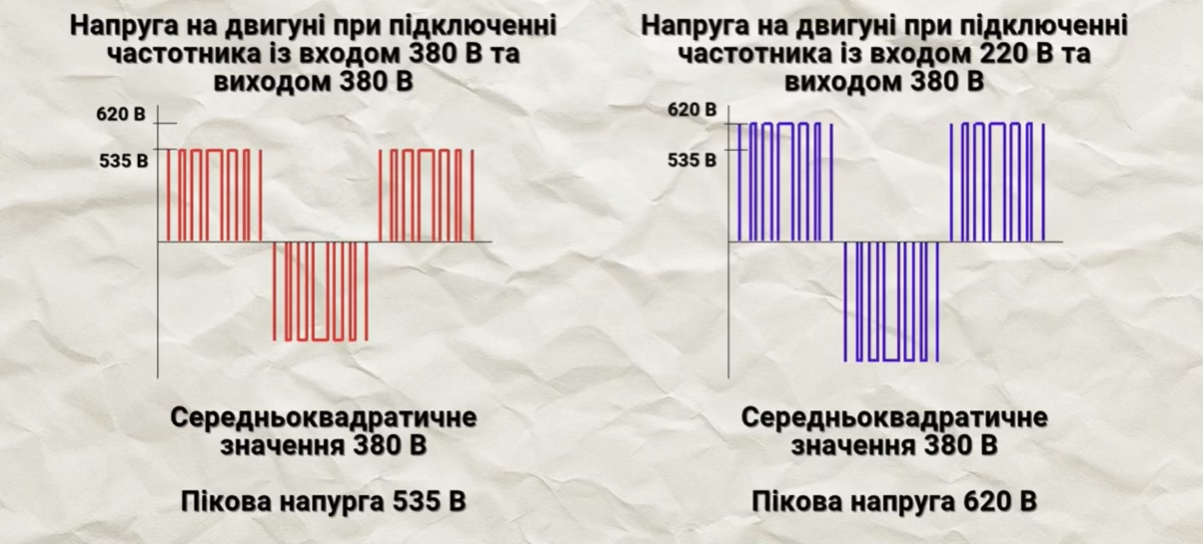

1) High peak voltages.

If for a conventional frequency converter this is a peak of 535V, then for this one it will be 620V, which is 15% higher

This is very bad for winding insulation, especially if the motor has been in operation for a long time, or for new cheap motors.

The longer the motor has been working, the faster the insulation will break down, and the motor will go for repair or replacement, but this will be a temporary solution to the problem.

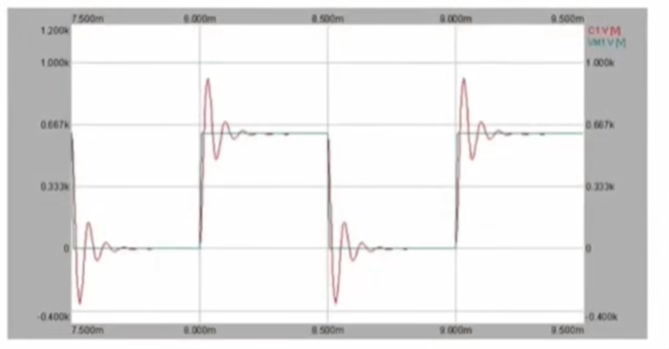

2) Impulse overvoltages

They occur in the cables running from the frequency converter to the motor. If the peak voltages are increased, then the impulse overvoltages will also be higher, especially when using long cables, for example, for submersible pumps or other installations. Also, to protect the motor, a motor choke must be used with such a frequency converter, as well as the shortest possible cable.

3) Component base of such a frequency converter

As a rule, the component base of such frequency converters, from the samples examined by our engineers, is very cheap, and the capacitance of the capacitors was underestimated for such an implementation. They were essentially modified from 3-phase models by soldering wires with surface mounting as shown in the pictures above, and that's it. At the same time, the capacitance of the capacitors was not increased as required by the calculation.

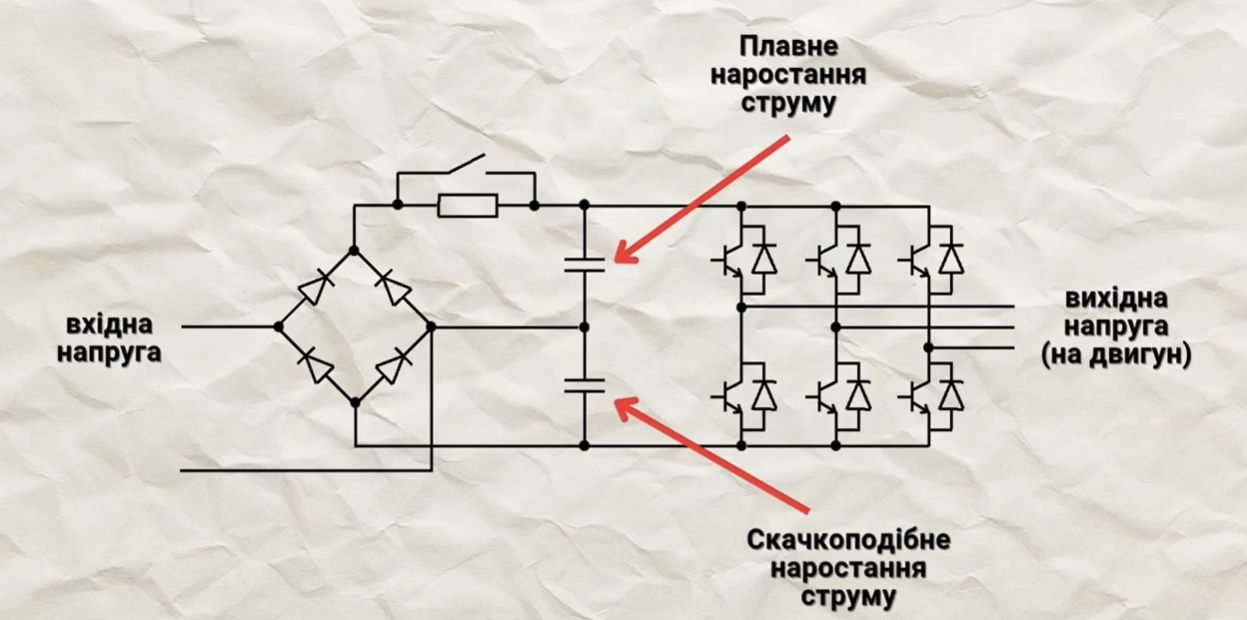

4) Poor circuitry

In a classic frequency converter design, the capacitor should be charged slowly through a charging resistor, which is shunted at the end of charging by a relay.

But in the "modified" one, the situation is somewhat different. Everything will be fine with the upper capacitor, but with the lower one, there will be jumps, which will negatively affect its service life, especially if cheap components are used there.

5) Increased consumption

When using such a frequency converter, the load on the phase increases. Carefully read what the input current will be, not the power but the current itself, and make sure that you can provide the necessary current.

So, let's summarize. If there is a motor for which only 3 wires are led out for connection (star connection 380V), then:

1) This motor can be taken to specialists who will disassemble the motor and bring out the remaining 3 ends of the windings to allow for a delta connection and use a frequency converter that converts 1-phase 220V to 3-phase 220V. This will be THE BEST SOLUTION. There will be no power loss. In principle, usually, this can be done yourself; there is a lot of video material on the Internet, and no special skills or knowledge are required for this.

2) If you still decide to use a 1-phase 220V to 3-phase 380V frequency converter, you should seriously consider using the shortest possible cable, installing a motor choke, using it as rarely and briefly as possible, and mentally saying goodbye to the motor, and in the case of connecting to a submersible pump, looking for a replacement. This is physics, and you can't cheat it.

3) Or purchase a 3-phase voltage source; yes, it will cost some money, but the motor will be intact.

If you have any questions or need clarifications or consultation, please contact our specialists. We will help you.