Energy and Water Savings Through Frequency Converters

Frequency converters have found wide application in residential, construction, and industrial water supply systems. This is one area of engineering where energy savings become noticeable within just a few months of using the converter. Let’s take a closer look at the cost-effectiveness that can be achieved with this equipment.

Control Algorithm and Energy Savings

You often hear phrases like: “We installed a frequency converter, but there are no energy savings.” In fact, the frequency converter allows for motor control, and the energy savings depend on the control algorithm. Let’s consider an example.

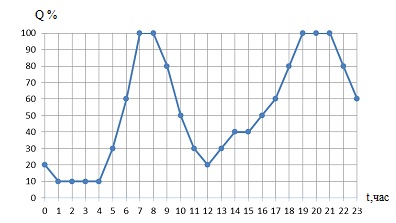

Suppose we have a daily water consumption schedule in an apartment building. If we calculate the average water consumption per hour, we get:

Qc= ∑Q/∑t=(20+10+10+10+10+30+60+100+100+80+50+30+20+30+40+40+50+60+80+100+100+100+80+60)/24=55%. This is equivalent (considering various nuances) to 70% of energy consumption.

Moreover, water consumption depends on the pressure in the system. Sometimes you may not guess what the current pressure is in the system, and random actions can lead to unnecessary waste. For instance, by turning on the faucet 15-20 times a day, you waste at least 3 liters of water unnecessarily.

Implementation of the Frequency Converter

Installing just the frequency converter allows you to control the pressure manually. For economic mode, it is necessary to implement a pressure sensor that will give commands to the frequency converter. Thus, the converter will maintain the required pressure by changing the frequency (motor speed). As water consumption decreases, the pump speed will also decrease, allowing for energy savings.

The savings from such an implementation consist of two parts: direct and indirect. Direct savings encompass the savings of electricity and water, while indirect savings relate to extending the lifespan of the pump and pipes.

Let’s consider an example with a 55 kW pump. Without a frequency converter, the pump operates at rated power, and the power consumption will be 5.5*24=132 kW per day. In a system with a frequency converter, we obtained a figure of 70%, which amounts to 5.5*0.70*24=92.4 kW. Thus, the energy savings per day is 132-92.4=39.6 kW. At a price of 0.5 UAH per 1 kW, the savings would be at least 20 UAH per day, totaling 20*365=7300 UAH per year.

Water Savings

According to the previous calculations, in a system with a frequency converter, each person uses an additional minimum of 3 liters of water per day. Over a year, this amounts to at least 1100 liters per person (65 apartments with 3 people each), resulting in a water savings of about 220 m³ per year from one building. At a price of cold water of 3.16 UAH per m³, this would be 220*3.16=700 UAH per year. For hot water (at a rate of 16.48 UAH per m³), the savings would be 220*16.48=3625 UAH.

Indirect Savings and Payback Period

Indirect savings involve controlling the motor's operation. In case of an emergency, the converter simply shuts off the pump and issues a malfunction message, preventing motor failure. By reducing maximum pressure in the system, the risk in cases of pipe rupture is also diminished. Repairing pipe leaks is more costly than replacing the motor.

Thus, the average savings from solutions based on a frequency converter for a 55 kW power will be around 8000 UAH per year. This means that the payback period for the system will be approximately one year. Similar calculations can also be done for hot water, where the payback period will also be less than a year depending on the power.

For quality advice regarding such solutions and their acquisition, you can contact us in the Contacts section.