This article is dedicated to the application of soft starters and frequency converters in sewage pumping stations (SPS) and water supply pumping stations. A brief summary of the article is presented in the picture below.

Let's consider in detail the advantages of using these devices. Problems and solutions will be summarized in a table.

Characteristic Problem | Proposed Solution | 100% Result |

Excessive currents during startup (starting currents) require the use of larger cross-section cables. Transitional processes "sag" the network, causing failures in starting equipment, leading to premature malfunction. | Installing frequency converters or soft starters significantly, if not completely, eliminates starting currents. | Increased lifespan of the pump and electric motor. |

At shutdown, especially during startup, water hammer occurs in the system, which can damage pipes and shut-off valves. | Soft start and stop functions reduce or completely eliminate water hammer. | Significant increase in the resource of the pumping unit, reduction in pipeline repair costs. |

Absence of fluid or air entering the pump leads to severe overheating or burning of bearings, causing the pump to fail. | An integrated load monitoring function continuously tracks the load level and provides reliable emergency shutdown of the pump when established norms are exceeded. | Prevention of pump breakdown, increased lifespan of the pumping unit, reduced repair costs. |

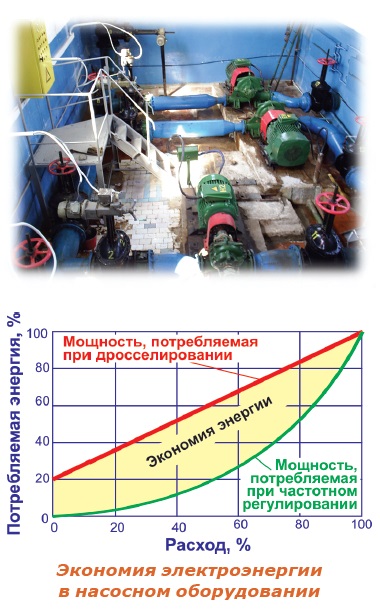

When changing a technological parameter (pressure or flow), the motor speed remains constant, leading to constant energy losses and premature wear of the equipment. | Activating the PID controller function built into the frequency converter and connected pressure sensor allows for adjustment of the electric motor's revolutions based on the pressure level. | Significant reduction in electricity consumption and simplification of the technological scheme. |

Sewage Pumping Stations (SPS)

When applying soft starters at SPS, we achieve:

- Reduction of starting currents and elimination of voltage drops;

- Reduction of hydraulic shocks during the starting and stopping of the electric motor;

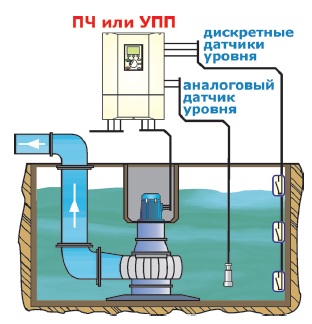

If frequency converters are also used, the following can be achieved:

- Remote control of SPS operation and visualization of the technological process on the operator's panel;

- Automatic maintenance of the required fluid level in the tank;

- Elimination of current loads and hydraulic shocks;

- Energy savings of up to 40%.

Water Supply Pumping Stations (WSPS)

When applying soft starters at WSPS, you can achieve:

- Reduction or complete elimination of hydraulic shocks in the system;

- Significant reduction of transient currents during electric motor startup and elimination of voltage drops;

- Reduced energy consumption during startup.

If frequency converters are applied, then it is possible to achieve:

- Complete elimination of hydraulic shocks;

- Support for the technological parameter (for example, pressure);

- Change of pressure according to a set schedule;

- Energy savings of up to 40%;

- Payback period of implementation of 6 months;

- Elimination of leaks caused by excess pressure in the pipes.

For more detailed information about the implementation of frequency converters for these systems, you can learn from our managers or technical support service. You can contact us using any convenient method listed in the Contacts section.