In this article, we will explore the main capabilities of implementing frequency converters in industry. You will be able to find solutions to your problems, or pay attention to important aspects regarding the functionality of frequency converters that can be applied in your project.

Cranes Systems

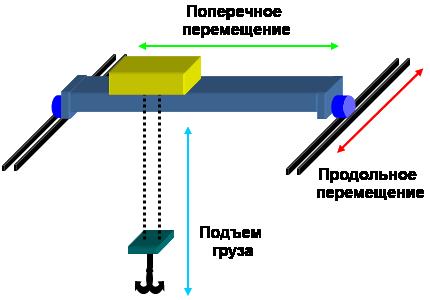

The key crane processes include: lifting and lowering loads, transverse and longitudinal movement of the hoist.

Task 1: Crane Beam

Lifting and lowering the load (vertical displacement):

- The need for high torque at low motor speeds, or holding it at a zero frequency (only with the help of frequency converter in conjunction with an encoder).

- Vector control using a feedback sensor (encoder).

- A dynamic braking module with high load capacity is needed. Braking resistors are also required to provide the necessary braking torque.

- Reverse control (direction of rotation).

- Motor brake control.

- Protection of the motor from short circuits, overvoltage, thermal protection, idle state protection, etc.

- Extending the lifespan of the motor.

- Soft acceleration and deceleration, avoiding jerks.

Longitudinal displacement of the load:

- One frequency converter controls two parallel-mounted motors.

- Soft acceleration and deceleration of the motor.

- Control of the direction of movement.

- Extending the lifespan of the motor.

- Protection of the motor from network issues.

Transverse displacement of the load:

- Low power of the motor compared to the longitudinal movement motors.

- Soft acceleration and deceleration of the motor.

- Control of the direction of movement.

- Protection of the motor from network issues.

- Extending the lifespan of the motor.

Solution 1:

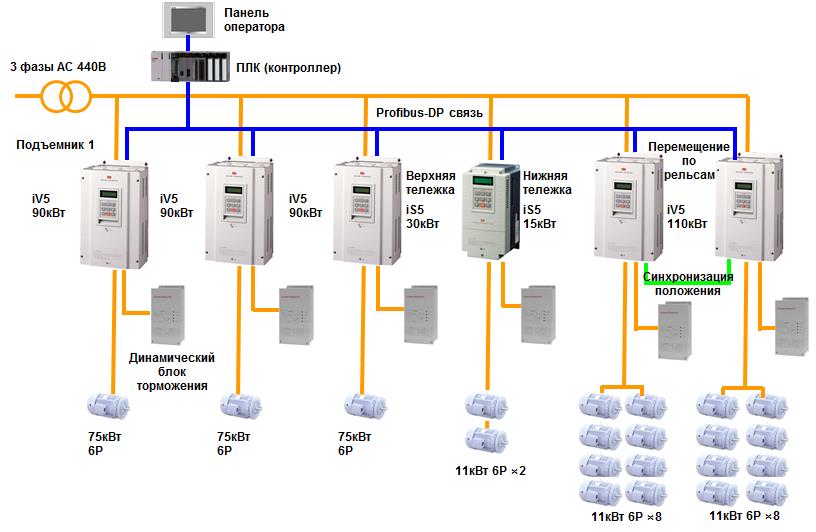

Task 2: Clamp Cranes (150 tons)

The clamp crane performs the movement of the bridge within the workshop, the movement of the trolley along the bridge, lifting the clamps, and gripping the workpiece. For this, vector control frequency converters with speed feedback are used, and braking resistors are installed to dissipate energy for 110–140 seconds at maximum load.

Solution 2:

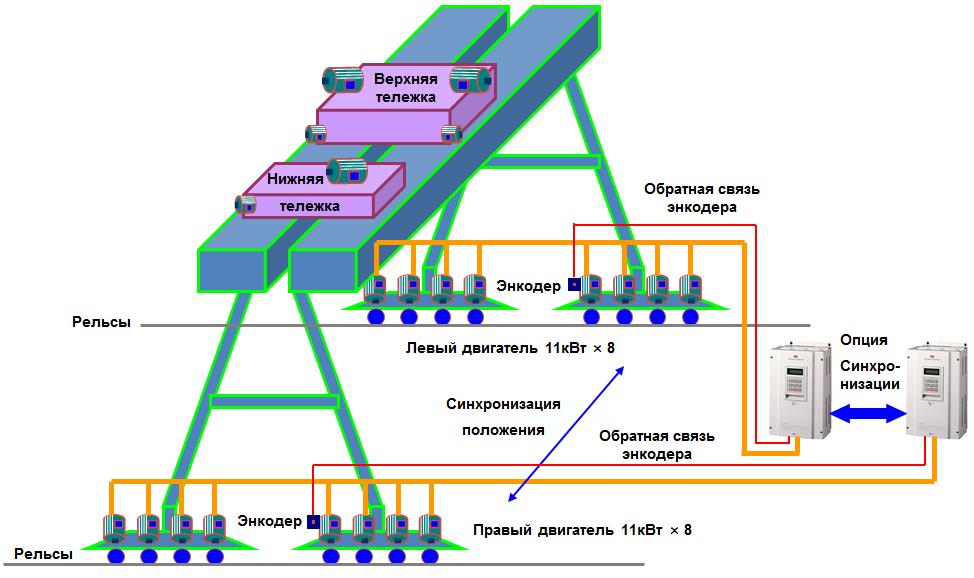

Task 3: Gantry Crane (300 tons)

One frequency converter controls 8 motors. Synchronization of movement (to the right, to the left) and control of the rotation frequency using feedback from one encoder for 8 electric motors (one encoder for right and left motors) is required.

Solution 3:

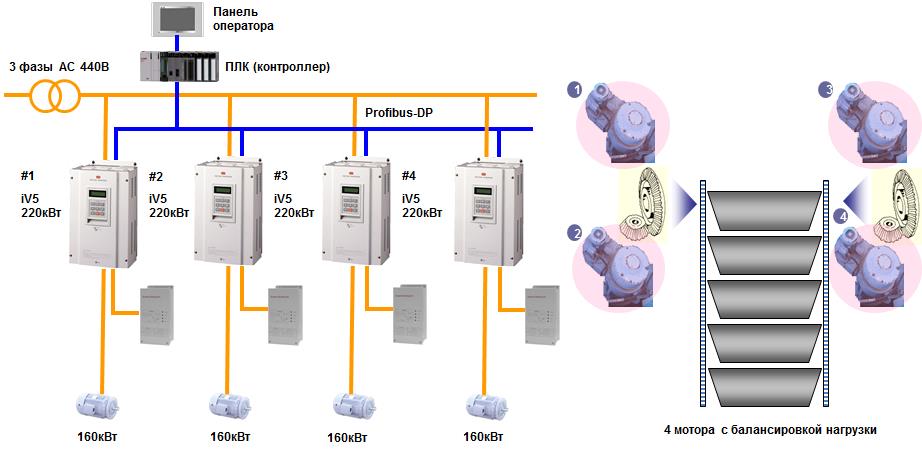

Task 4: Loading Mechanisms for Unloading Coal from Ships

- Control of the elevator bucket with the help of 4 motors, which requires a function for balancing the bucket load.

- Control of the motor operation.

- Soft acceleration and braking, reducing mechanical shocks in the system.

Solution 4:

Winding Machines

Task 5:

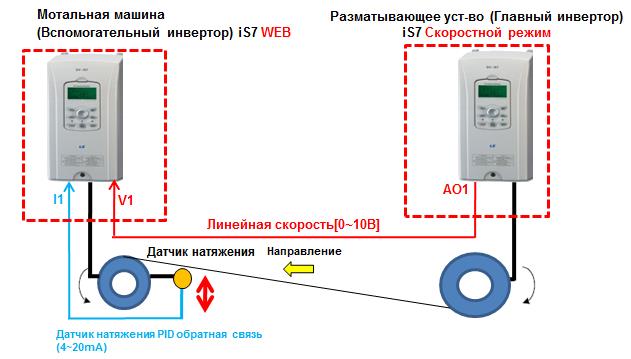

The task of the rewinder device is to ensure a constant tension of the material between the spools. When the radius of the spool changes, the rotation frequency of the shaft changes, and the frequency converter must adjust this frequency. It is necessary to provide run-up control for further integration with a load cell or force sensor.

The following functions are required:

- PID control for constant adjustment of frequency in connection with changes in spool diameter.

- Control of the spool diameter.

- Break control — using a tension sensor.

- Operating mode: V/F with feedback sensor.

Solution 5:

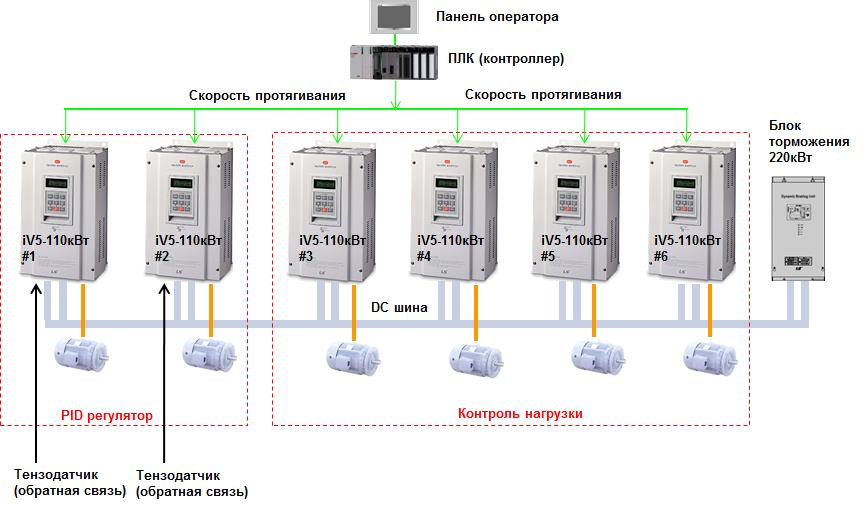

Task 6: Rolling Mill

In rolling mill machines, the main goal is to provide equal pressure on the deformed material from the rollers that are rotating.

Theater

Task 7: Opening the Curtains in the Theater

The main problem is to ensure the synchronization of curtain movement to the right and left, as well as its lifting.

Solution 7:

Implementation of a frequency converter with a synchronous control board.

Task 8: Lifting the Stage in the Theater

The main problem is to ensure the synchronization of speed of movement (lifting/lowering) of the stage component and the safety of personnel and artists.

Solution 8:

Implementation of a frequency converter with a synchronous control board.

.jpg)