The Problem of Connecting a Three-Phase Motor to a Single-Phase Network

The problem of connecting a three-phase motor to a single-phase electrical network is familiar to many, especially those living outside of cities. Such a situation often arises when using household mechanisms like circular saws, compressors, concrete mixers, and others.

Disadvantages of Traditional Solution

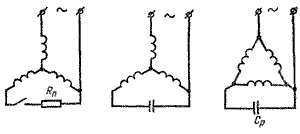

One of the most well-known solutions is connecting capacitors to one of the motor phases to provide phase shifting. However, this approach has significant drawbacks:

- After using capacitors, the power consumption increases, which lowers the motor's efficiency.

- The starting torque decreases, requiring startup with minimal load (specifically, for circular saws, the motor needs to be lifted for starting at idle).

- The rotating field inside the motor becomes pulsating rather than circular. This can be noticed when a light bulb is turned on during the motor's operation: the bulb will flicker — the effect of the capacitors' operation.

- This scheme can cause voltage fluctuations in the electrical network, which powers other household appliances, threatening their failure.

- Capacitors do not provide control over the motor.

Alternative Solution: Frequency Converter

We propose another solution — using a frequency converter with 1 phase 220V input and 3 phase 220V output. When connecting a three-phase motor rated for 380V, if connected in a star configuration, it needs to be switched to a delta configuration to operate at 220V.

The advantages of this solution are:

- The ability to adjust the motor's rotation speed.

- Ensuring smooth start and stop of the mechanism, which reduces its wear and mechanical load.

- Many functions that can be adapted for specific applications.

- Energy savings due to optimal consumption, depending on the correctness of the frequency converter settings.

Contacts and Support

If you have questions regarding technical support or purchasing frequency converters, you can contact us through any of the suggested methods in the Contacts section.