An asynchronous electric motor is one of the key components in modern industrial and household systems. Its main function is to convert electrical energy into mechanical work. High reliability, simplicity of design, and cost-effectiveness have made this type of motor very popular. However, during its operation, certain challenges may arise, particularly high starting currents. When the motor is directly connected to the network, these currents can exceed the nominal value by 10–20 times. This creates a significant load on the electrical network and switching equipment, posing a risk of damage, especially with frequent starts or in the case of high-power motors.

Problems related to high starting currents

High starting currents can lead to the following issues:

- Overloading of power transformers, which may cause overheating or emergency shutdown.

- Voltage drops in the network, negatively affecting the operation of other devices.

- Rapid wear of switching elements such as contactors or circuit breakers.

- Risk of motor winding damage due to excessive heating.

To mitigate these risks, there are several methods for limiting starting currents, among which the most popular is the "star-delta" connection scheme.

What is the "star-delta" scheme?

The "star-delta" scheme is a method of reducing starting currents by changing the way motor windings are connected. Initially, the windings are connected in a "star" configuration, which reduces the current to 1/3 of the nominal value. Once the motor reaches a certain speed, the windings switch to the "delta" configuration, which provides maximum power.

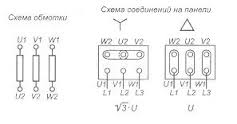

This scheme is effective, but it can only be applied to motors that support such switching. For this, the motor's connection box must have six terminals that allow changing the connection configuration. The image below shows what such a connection box looks like:

Determining motor parameters

If access to the connection box is unavailable, information about the "star-delta" scheme support can be found on the motor nameplate. It contains data on nominal voltage and current in each mode. For example, when connected in a "star" configuration, the nominal voltage is usually 690 V, and the current is significantly lower than when connected in a "delta" configuration with a voltage of 400 V.

Based on this data, a motor startup algorithm can be built:

- First stage: start the motor in the "star" configuration, which reduces the starting current.

- Second stage: after 5–10 seconds (depending on the mechanism and inertia), the windings switch to the "delta" configuration. This ensures the motor's full power.

Connection scheme

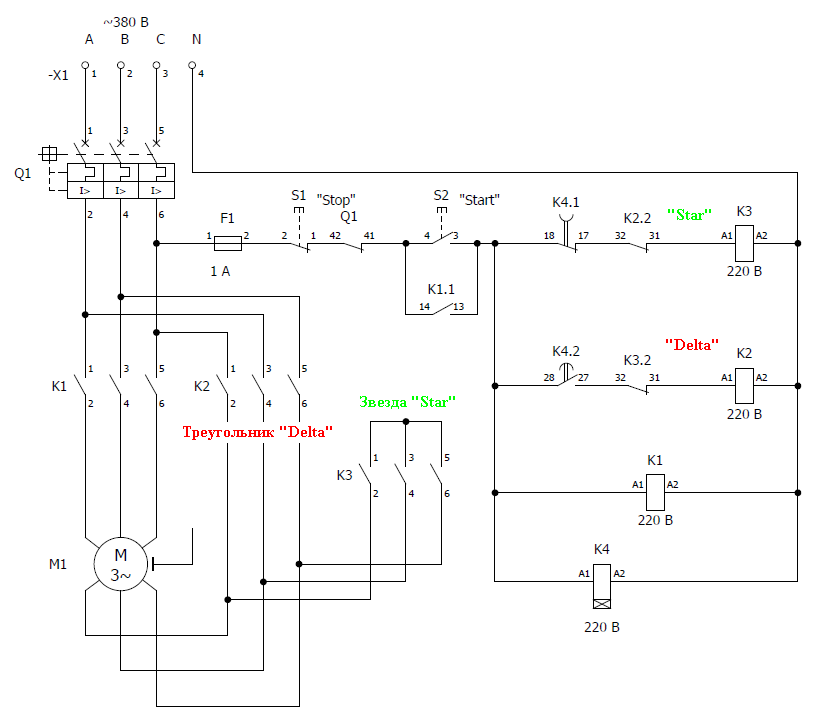

To implement the "star-delta" scheme, switching equipment consisting of three contactors, a thermal relay, and a time relay is used. Below is the wiring diagram:

Principle of operation

The scheme operates according to the following algorithm:

- When the "Start" button (S2) is pressed, power is supplied to the K1 contactor, which closes the windings in the "star" configuration. Simultaneously, the K4 time relay is activated, starting the countdown.

- After a set time (usually 5–10 seconds), the K4 relay turns off the K1 contactor and turns on the K3 contactor, switching the windings to the "delta" configuration.

- To stop the motor, the "Stop" button (S1) is pressed, which breaks the power circuit.

The interlock contacts K2.2 and K3.2 ensure protection against simultaneous activation of K2 and K3 contacts, which could cause a short circuit.

Advantages and limitations

The "star-delta" scheme has several advantages:

- Reduces starting current by three times.

- Decreases mechanical load on the motor and connected equipment.

- Simple to implement, provided the necessary switching equipment is available.

However, it also has limitations:

- Not suitable for motors with a fixed winding configuration.

- Requires additional expenses for time relays and contactors.

- Mechanical oscillations may occur during the switch from "star" to "delta."

Conclusion

The "star-delta" scheme is an effective way to reduce starting currents and protect the electrical network from overloads. Its use extends the lifespan of equipment and ensures stable system operation. It is important to correctly select the time relay parameters and properly configure the scheme to avoid damage to the motor or switching equipment.