VFD-CP2000 Frequency Converters from Delta Electronics

The Taiwanese giant Delta Electronics has introduced a new, more affordable series of frequency converters VFD-CP2000, designed for pumps and fans. Despite the reduced cost, this series has significant potential and replaces the previous VFD-F series. The motor power range supported by this series varies from 750 W to 560 kW.

The development of this series utilized the latest achievements in the field of electric drive. One key aspect is the implementation of an energy-saving algorithm that allows for voltage reduction at the output of the frequency converter, providing up to 30% additional energy savings even when operating at rated frequency. Moreover, the VFD-CP2000 frequency converters are equipped with a built-in programmable logic controller with a memory of up to 10,000 steps, which allows for easy integration into automated systems.

The VFD-CP2000 frequency converters come with a graphic display that shows parameters such as output frequency, voltage, and current. This allows users to visualize data in real-time, and with additional software, detailed graphical representation of the aforementioned values is possible.

Main Features and Characteristics of VFD-CP2000

The VFD-CP2000 frequency converters in the basic configuration have:

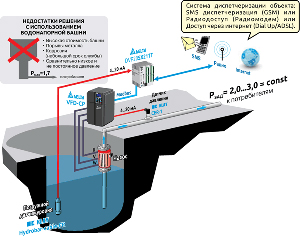

- Support for various expansion boards, providing additional capabilities (PROFIBUS DP, DEVICENET, CANOPEN, ETHERNET/IP, MODBUS TCP interfaces; additional output board for cascading control of up to 6 pumps, etc.).

- A PID controller function for precise process control.

- A special FIRE MODE function for emergency operation, allowing for smoke removal and fire suppression.

For powerful systems, the option of water cooling for the frequency converter is available, and vector control mode is also supported.

Applications

The VFD-CP2000 frequency converters have a wide range of applications, including:

- Ventilation systems (blowers, fans, cooling towers, etc.).

- Heating systems (circulation pumps).

- Water supply (pumps, pumping stations with cascading operation mode).

- Chemical, textile, paper, and wood processing industries.