Vector Control of Electric Drives in Industry

Today, vector control of electric drives has found broad application in industry. Devices such as frequency converters, which implement motor control based on vector control algorithms, are used during the development of electric drives for modern machines.

Advantages of Vector Frequency Converters

The area of application for frequency converters based on vector control is determined by the following main advantages:

- The ability to withstand significant loads.

- The capability to maintain constant torque on the shafts of electric motors.

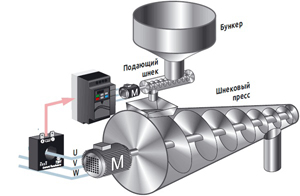

The ability to withstand large loads allows frequency converters to be used in mechanisms such as extruders and deep well pumps, which require a high starting torque during operation. For example, to start a "clogged" pump, it is advisable to use modern vector converters.

Maintaining constant torque on the shafts of electric motors is critically important for machine engineering. For instance, if the torque on the spindle of a lathe constantly varies, it leads to a deterioration in the quality of the machined surfaces of the workpieces and increases wear on the cutting tools.

Modernization of Equipment

Another important factor influencing the choice of vector frequency converters is the desire to modernize existing equipment in enterprises. For this reason, some manufacturers produce converters that combine the functionality of vector control with voltage-frequency control.

Modernization significantly reduces operating costs by minimizing losses, especially during emergency situations. Due to the decrease in the number of spare parts required for storage, enterprises can cut costs associated with equipment operation. In the event of an emergency, a faulty converter can be replaced with a similar one from another section.

Advantages of Vector Frequency Converters

Although frequency converters with vector control have a high cost, they provide significant benefits resulting from their use. Industrial enterprises that use this equipment will be able to:

- significantly improve product quality;

- increase production volumes;

- reduce operating costs, especially for periodic maintenance;

- greatly expand the range of products that meet global standards.