Energy Saving in Electric Drives of Centrifugal Mechanisms

The maximum energy-saving effect is achieved in the electric drives of centrifugal mechanisms. In this type of equipment, the energy consumed and the power provided by the drive are proportional to the indicated rotation frequency cubed. Variations in frequency, when the motor is supplied by a frequency converter, have a significant impact on energy efficiency.

It is evident that if, in the process of controlling the performance of a pump or fan, whose drive is connected to a frequency converter, the voltage frequency is reduced from 50 to 40 Hz, electricity consumption will decrease by almost half. This is explained by the fact that electricity consumption is proportional to the cube of the frequency change. As a result, we obtain: (40/50)3 = 0.512.

Characteristics of Pumps and Fans

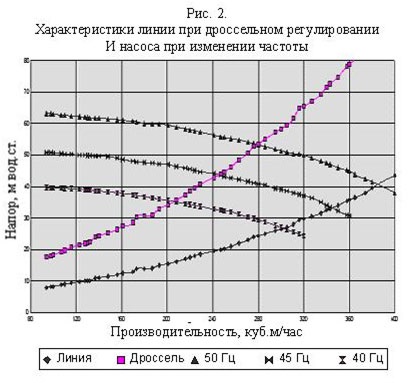

The basic characteristic of centrifugal pumps, compressors, and fans is the dependence of the head (H) on the flow rate (Q). Typically, such dependencies are represented by Q-H graphs for various values of the unit's rotational frequency. In the case of special applications, they need to be considered alongside the characteristics of various hydraulic lines under conditions of open and partially closed throttles, obtained during experiments.

The graph presents the head characteristics of the pump model D320-50 (H=50 mm water column, Q = 320 m3/hr), which exist in relation to different rotational frequencies: 0.9 (45 Hz), 0.8 (40 Hz), 1 (50 Hz). When constructing these lines, it is taken into account that the flow rate is proportional to the rotational frequency, and the head – to the square of that frequency.

The points of intersection of the head line define the operating mode of the pump in conjunction with the pipeline. The implementation of frequency control, which varies the head characteristic of the unit, allows for a departure from the unprofitable throttle performance regulation that affects the shape of the characteristic line through the artificial increase of the hydraulic resistance needed to overcome it.

Advantages of Frequency Control

The main advantage of switching to frequency regulation of the electric motor speed is the ability to optimize the operating mode of technological equipment.

- Maximum energy savings due to the gentle operation of electrical equipment.

- Significant reduction of loads on technological equipment, including dynamic impacts, which prolongs the operational life of the units.

- Reduction of repair costs.

- Electricity tariffs are higher for municipal organizations and lower for enterprises that have their own generating capacities.

- Reduction of the payback period of frequency converters, which is particularly beneficial for high-power equipment, as the specific cost of the frequency converter decreases with increasing power.

Frequency control is a modern and effective method that allows for more economical use of energy resources and prolongs the service life of equipment. The payback for such equipment can range from 0.7 years and more.